23/08/2022

Technology is constantly changing how we perform tasks in professional fields. In HVAC, like any other industry, there are technological advancements which are brought about by the need to save energy and protect the environment.

According to Sikhulile Nhassengo, Director at Maninga Engineering, in an HVAC system, refrigerant gas is used to heat the medium that is used to transfer energy. Gases such as R22; R123; R406A and R409A are amongst the gases which are being phased out due to their negative impact on the environment. They are being replaced with more environmentally friendly gases such as R410A; R32; HFO1233zd and HFO1234ze.

Machinery is another aspect which should be taken into consideration. Systems are changing from conventional methods of heating and cooling to more improved methods. For instance, an air-cooled chiller is preferred in our South African climatic conditions, as it uses much less water to cool or heat the systems as compared to the water-cooled chiller that requires a cooling tower which uses a lot of water and usually requires a much larger footprint to place the system.

Nhassengo explains that another technologically improved system in the HVAC field is the TABS (Thermally Activated Building System). This uses a chiller unit and pipes installed in the slabs of the building to control the ambient temperature. The TABS would decrease the ambient temperature in hot days of the month to achieve a cooler desired temperature. The system would take approximately 8 hours to reach the set point temperature depending on the size of the building. The building will stay at the set temperature for longer periods without the need to run the chiller and utilise more energy, as the building would store energy.

There is also the chilled beam technology, which uses chilled water and the chilled beam itself. This technology requires very few components and very few moving parts, thus it is very easy to maintain. In cooling mode, the chilled water is fed into the chilled beam from the chiller and run through the coils inside the chilled beam. Then, air is forced through the coils where transfer of energy from the chilled water to the air takes places. The air will be cool and the chilled beam will have a slightly higher temperature due to the energy transfer. The mixing of return air and fresh air takes place on the spot in the chilled beam. Therefore, there is no need for ducting the return air and thus saving space, reducing the cost of installation and resulting in less energy losses due to the reduced distance travelled by the air.

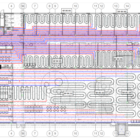

One of Maninga Engineering’s (Pty) Ltd projects which highlights this technology is the WCLMPUR_T01: Commerce, Law and Management (CLM) Building Development Project. Maninga Engineering was tasked with providing a sustainable HVAC solution for the client. This involved analysing the thermal environmental conditioning spaces – TABS. TABS are increasingly used for energy efficiency and economical cooling and heating of commercial buildings. Thereby, the building structure is used as thermal storage, allowing the use of renewable energy sources.

In this project the CLM has two systems: Active Chilled Beam for meeting rooms and TABS for the entire building. Superior equipment has been used in this project – only the chiller is used to heat the water. The efficiency comes from the radiant energy. Radiant heating is absorbed from the sun, which makes the system more efficient.

According to Sikhulile Nhassengo, Director at Maninga Engineering, in an HVAC system, refrigerant gas is used to heat the medium that is used to transfer energy. Gases such as R22; R123; R406A and R409A are amongst the gases which are being phased out due to their negative impact on the environment. They are being replaced with more environmentally friendly gases such as R410A; R32; HFO1233zd and HFO1234ze.

Machinery is another aspect which should be taken into consideration. Systems are changing from conventional methods of heating and cooling to more improved methods. For instance, an air-cooled chiller is preferred in our South African climatic conditions, as it uses much less water to cool or heat the systems as compared to the water-cooled chiller that requires a cooling tower which uses a lot of water and usually requires a much larger footprint to place the system.

Nhassengo explains that another technologically improved system in the HVAC field is the TABS (Thermally Activated Building System). This uses a chiller unit and pipes installed in the slabs of the building to control the ambient temperature. The TABS would decrease the ambient temperature in hot days of the month to achieve a cooler desired temperature. The system would take approximately 8 hours to reach the set point temperature depending on the size of the building. The building will stay at the set temperature for longer periods without the need to run the chiller and utilise more energy, as the building would store energy.

There is also the chilled beam technology, which uses chilled water and the chilled beam itself. This technology requires very few components and very few moving parts, thus it is very easy to maintain. In cooling mode, the chilled water is fed into the chilled beam from the chiller and run through the coils inside the chilled beam. Then, air is forced through the coils where transfer of energy from the chilled water to the air takes places. The air will be cool and the chilled beam will have a slightly higher temperature due to the energy transfer. The mixing of return air and fresh air takes place on the spot in the chilled beam. Therefore, there is no need for ducting the return air and thus saving space, reducing the cost of installation and resulting in less energy losses due to the reduced distance travelled by the air.

One of Maninga Engineering’s (Pty) Ltd projects which highlights this technology is the WCLMPUR_T01: Commerce, Law and Management (CLM) Building Development Project. Maninga Engineering was tasked with providing a sustainable HVAC solution for the client. This involved analysing the thermal environmental conditioning spaces – TABS. TABS are increasingly used for energy efficiency and economical cooling and heating of commercial buildings. Thereby, the building structure is used as thermal storage, allowing the use of renewable energy sources.

In this project the CLM has two systems: Active Chilled Beam for meeting rooms and TABS for the entire building. Superior equipment has been used in this project – only the chiller is used to heat the water. The efficiency comes from the radiant energy. Radiant heating is absorbed from the sun, which makes the system more efficient.